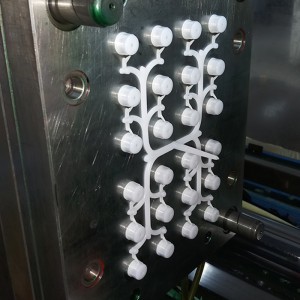

Caaryada joogsiga joogsiga ah waa aalad loo isticmaalo habka wax soo saarka si loo soo saaro cowska joogsiga, kuwaas oo ah valves loo isticmaalo in lagu xakameeyo socodka dareeraha ama gaaska codsiyada kala duwan, sida qalabka caafimaadka ama qalabka shaybaadhka. Halkan waxaa ah saddex siyood oo caaryada joogsiga joogsiga ahi u shaqeyso: Naqshadeynta Caaryada iyo Abuuridda daloolka: Caaryada joogsiga waxaa loo qaabeeyey si ay u abuurto qaabka la doonayo iyo shaqeynta cockka joogsiga. Waxay ka kooban tahay laba ama in ka badan, oo inta badan ka samaysan bir, kuwaas oo isu yimaada si ay u sameeyaan hal ama dhowr godad oo walxaha dhalaalka ah lagu duro. Naqshadeynta caaryada waxaa ka mid ah sifooyinka lagama maarmaanka ah, sida dekedaha laga soo galo iyo kuwa ka soo baxa, sagxadaha daboolka, iyo hababka xakamaynta, si loo hubiyo in si sax ah loo shaqeeyo joogsiga joogsiga.Molten Material Duritaan: Marka caaryada la dhigo oo si ammaan ah loo xiro, walxaha dhalaalka ah, sida caadiga ah heerkulbeeg ama elastomeric, ayaa lagu duraa godadka cadaadiska sare. Cirbadda waxa lagu sameeyaa mashiino khaas ah, sida mishiinka wax-qaabeeya ee duritaanka, kaas oo ku qasba walxaha la mariyo kanaalada iyo gudaha godadka caaryada. Qalabku wuxuu buuxiyaa godadka, qaadashada qaabka naqshadeynta joogsiga. Qaboojinta iyo ka saarista: Ka dib marka walxaha dhalaalidka ah lagu duro caaryada, waa laga tagay si loo qaboojiyo oo loo adkeeyo. Qaboojinta waxaa lagu fududayn karaa iyada oo la dhex wareejinayo qaboojiyaha dhexda caaryada ama isticmaalka taarikada qaboojinta. Marka maaddadu ay xoojiso, caaryada waa la furayaa, iyo joogsiga joogsiga ee dhammaatay ayaa laga soo saaraa godadka. Soo saarista waxaa lagu gaari karaa habab kala duwan, sida biinanka ejector ama cadaadiska hawada. Tallaabooyinka xakamaynta tayada, oo ay ku jiraan kormeerida cilladaha iyo saxnaanta cabbirka, ayaa laga yaabaa in la sameeyo heerkan si loo hubiyo in joogsiga joogsiga ahi uu buuxiyo shuruudaha loo baahan yahay. Caaryada waxay u ogolaataa wax soo saarka wax ku ool ah oo joogto ah ee joojinta joogsiga, kuwaas oo si ballaaran loogu isticmaalo warshadaha kala duwan ee codsiyada xakamaynta dareeraha.